Dit ben ik! Ik ben een enthousiasteling voor ontwerp en techniek. Voor mijn plezier zoek ik altijd alles tot de bodem uit (deze website heb ik zo ook gemaakt, ben benieuwd of je alle extra functies hebt kunnen vinden).

Dit ben ik! Ik ben een enthousiasteling voor ontwerp en techniek. Voor mijn plezier zoek ik altijd alles tot de bodem uit (deze website heb ik zo ook gemaakt, ben benieuwd of je alle extra functies hebt kunnen vinden).

Samen met mede-student Timo heb ik het bedrijf WAT-design opgericht, waarbij we onszelf proberen uit te dagen om nieuwe ideeën te onderzoeken en te testen, dit doen we vooral tijdens Koningsdag. Hieruit zijn bijvoorbeeld de oorbelletjes en sleutelhangers van vinylplaten ontstaan, maar ook de zeephouders die we maakten van resthout met onze CNC-machine en andere producten gebaseerd op reststromen. Wat-design is voor ons een manier om alternatieve producten te creëren uit restmateriaal, wat een hobby en passie voor ons is.

Ik probeer altijd bezig te zijn met mijzelf ontwikkelen en ken mijn valkuilen daarom ook goed. Daarom heb ik tijdens mijn minor periode gekozen voor de Minor Da Vinci. Hier heb ik verschillende technieken geleerd die me als persoon en als ondernemer sterker en assertiever maken. Een aantal technieken die ik heb toegepast zijn de Kaizen-methode, waarbij je kleine, periodieke veranderingen doorvoert om continu te verbeteren, en de Design Thinking-methode, die helpt om gebruiksvriendelijke en innovatieve oplossingen te creëren. Daarnaast leerde ik de techniek van Reframing, waarbij je een situatie evalueert vanuit het perspectief van een ingebeelde professional, zonder meteen naar oplossingen te zoeken. Deze techniek helpt je om problemen anders te bekijken en diepere inzichten te verkrijgen, waardoor je een beter begrip krijgt van wat er echt speelt voordat je tot concrete oplossingen komt.

Het spuitgietproces en het vergroten van functionaliteit stond centraal bij dit project. De Makhet bouwventilator is gebaseerd op Makita en heeft als extra functionaliteit de mogelijkheid om de luchtkwaliteit in zijn omgeving te meten en de gebruiker te waarschuwen als deze verslechtert of er een ongebruikelijke stof wordt gedetecteerd. Hieronder een montage-video van hoe het product is opgebouwd.

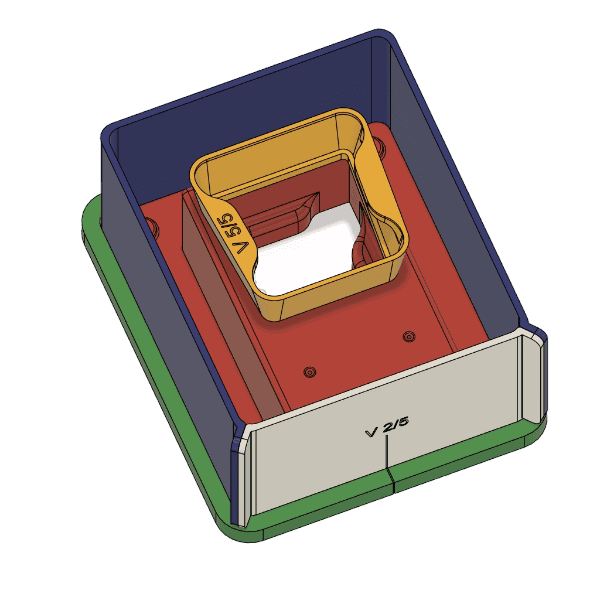

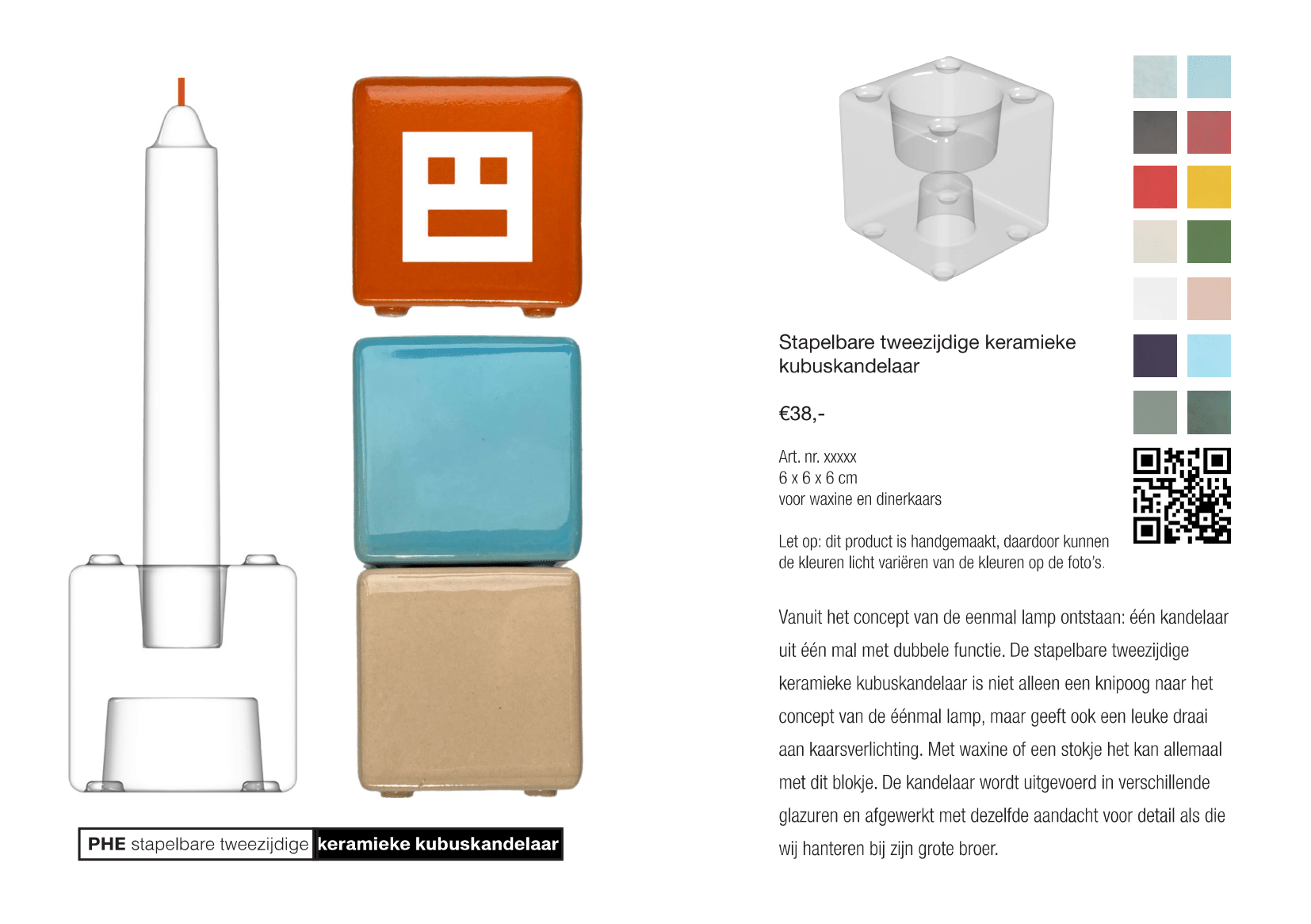

In mijn stageperiode bij Piet Hein Eek heb ik een project gedaan waarbij ik 3d-geprinte mallen heb ontworpen voor het efficiënter gieten van gipsen mallen voor keramiek gieten. Omdat dit zo goed beviel krijg ik daar nu na mijn stage nog opdrachten voor, hier een voorbeeld van een project waarbij het bedrijf een reconstructie wilde van al bestaande gipsen mallen (rechter foto). Hieronder 1 van de 4 mallen voor de éénmal-lamp van PHE.

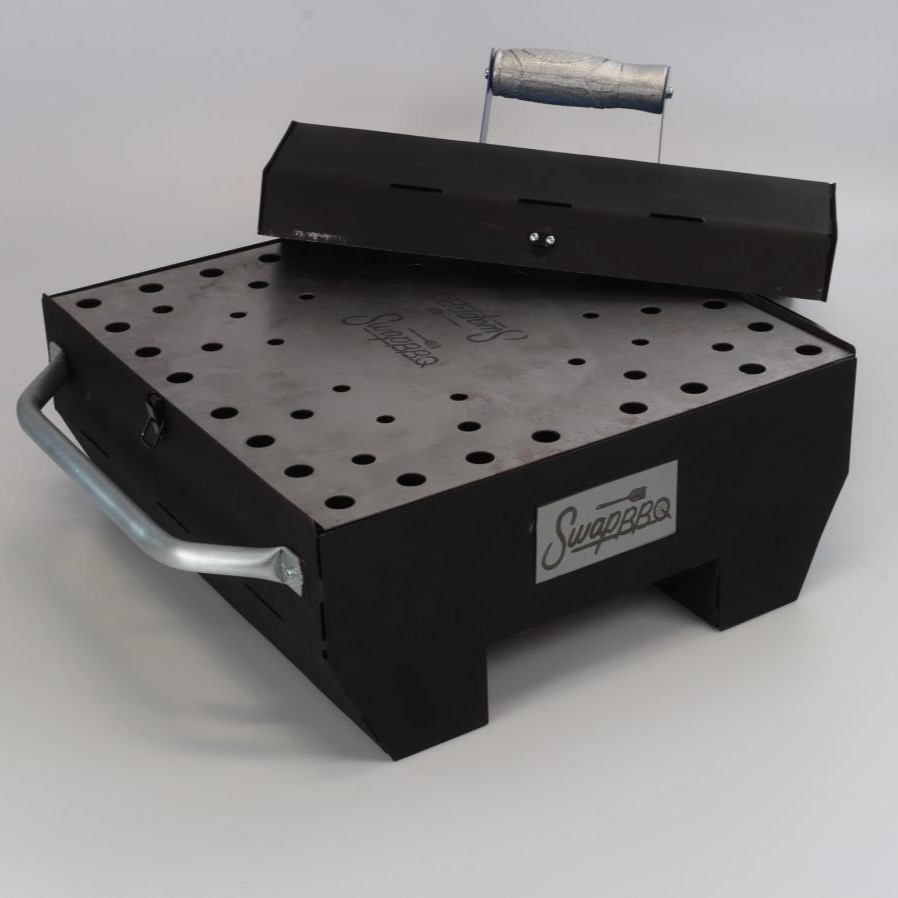

Het Swap-BBQ concept is een BBQ die voorop een swapfiets te bevestigen is. Het idee zou zijn dat de reeds bestaande Swapfiets locaties de BBQ zouden kunnen uitgeven en de gebruiker na gebruik het daar weer kan inleveren waarbij de kosten direct van het abonnement worden verrekend. Bij dit project heb ik geleerd om met DXF formaten te werken voor het uitsnijden van plaatwerk dat daarna door middel van vouwen en puntlassen wordt bevestigd. De binnenvorm is conisch en zorgt voor een goede verspreiding van de hitte zodat deze efficiënter werkt.

Bij dit project heb ik veel kunnen leren over het maken van bouwtekeningen voor lasconstructies en het buigen van plaatwerk. Hiernaast een overview tekening (zonder bemating) van een kar die ik heb gemaakt tijdens mijn stage bij Piet Hein Eek. Het idee is dat er een tafelblad aan wordt bevestigd. Doordat dit blad om het middelpunt van de as draait kan je gemakkelijk het blad omdraaien, dit bespaart de spuiters een hoop tijd en rugklachten. Voorheen draaide ze de tafel met de hand en moest er tussendoor worden gewacht tot de andere helft droog was voordat het kon worden omgedraaid. De foto is van een afvalhouten tafel van PHE in de kar.

Bij dit project heb ik veel kunnen leren over het maken van bouwtekeningen voor lasconstructies en het buigen van plaatwerk. Hiernaast een overview tekening (zonder bemating) van een kar die ik heb gemaakt tijdens mijn stage bij Piet Hein Eek. Het idee is dat er een tafelblad aan wordt bevestigd. Doordat dit blad om het middelpunt van de as draait kan je gemakkelijk het blad omdraaien, dit bespaart de spuiters een hoop tijd en rugklachten. Voorheen draaide ze de tafel met de hand en moest er tussendoor worden gewacht tot de andere helft droog was voordat het kon worden omgedraaid. De foto is van een afvalhouten tafel van PHE in de kar.

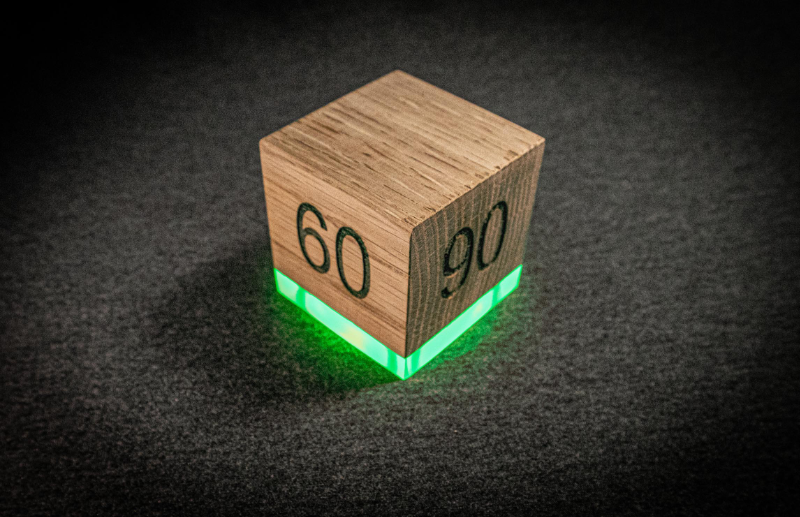

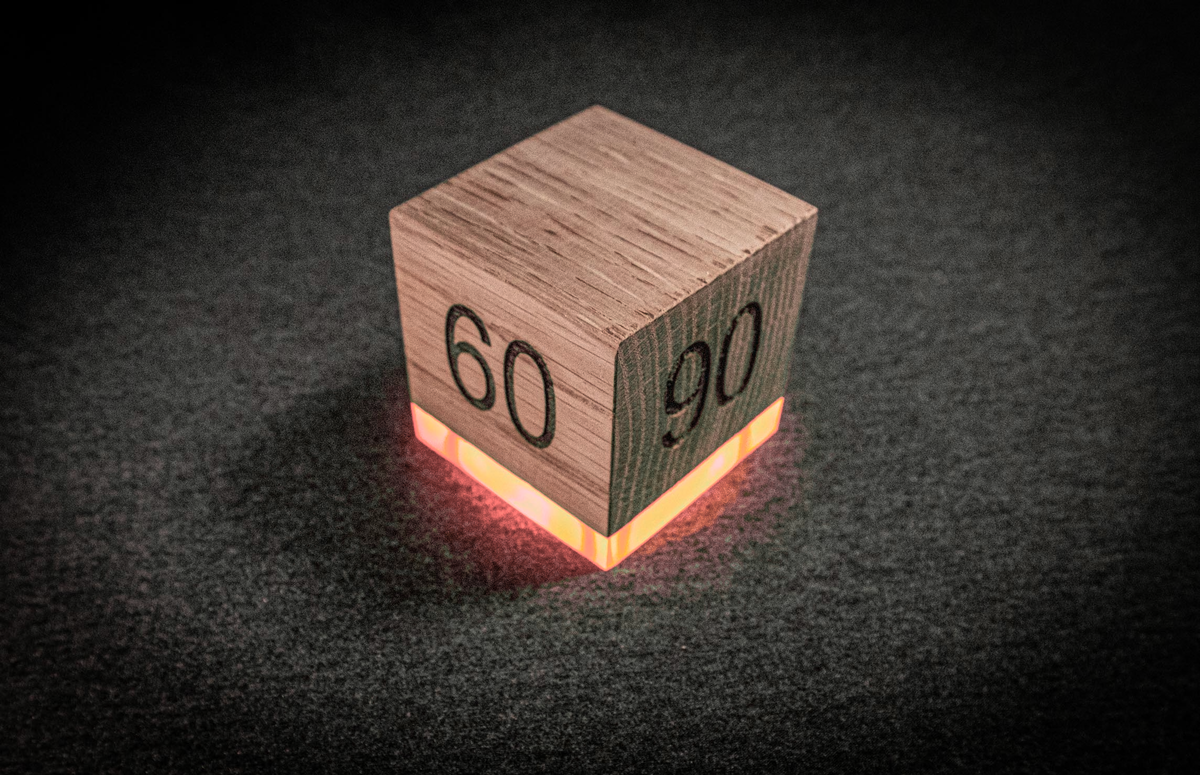

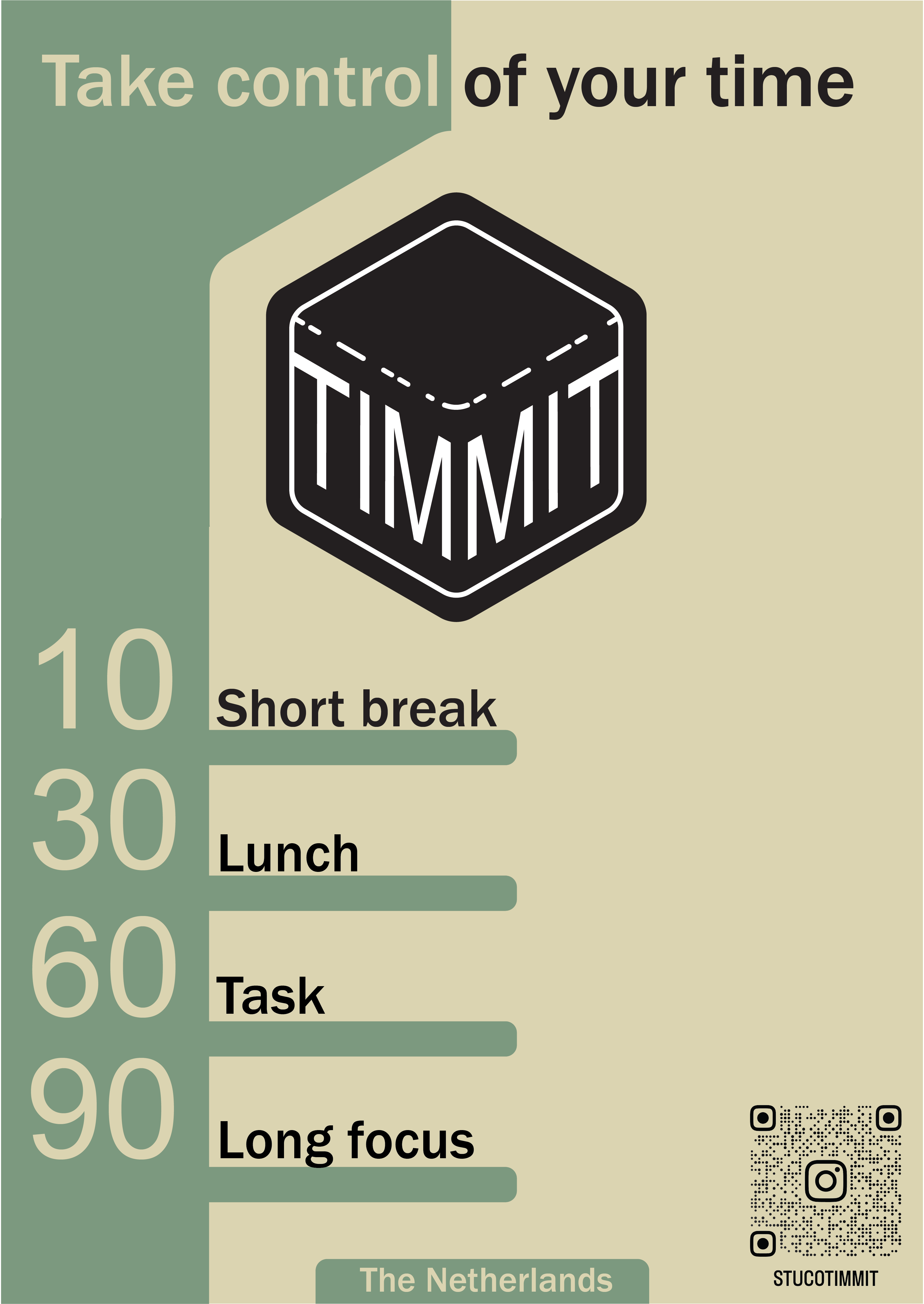

De Timmit is een tool die ik samen met arbeidsdeskundigen en studenten Bedrijfskunde en Industrieel Product Ontwerpen heb ontwikkeld. Het doel is om mensen die moeite hebben met tijdmanagement te helpen weer grip te krijgen op hun tijd. Timmit werkt door middel van een visuele timer en gekleurde lampjes die aangeven wanneer een taak of pauze is afgelopen.

Op vier van de zes vlakken van de Timmit staan tijden aangegeven in minuten. Door de gewenste tijd naar boven te zetten, begint de timer af te tellen. Gedurende de looptijd begint de transparante kant van het apparaat te veranderen van rood naar groen, wat aangeeft aan de omgeving dat de gebruiker weer beschikbaar is. De tijden zijn gebaseerd op onderzoek van arbeidsdeskundigen en helpen bij het optimaliseren van werk- en rustintervallen:

- 10 minuten: Een goed moment voor een korte pauze

- 30 minuten: Ideaal voor een lunchpauze

- 60 minuten: Voor geconcentreerd werk met een korte pauze erna

- 90 minuten: De maximale spanningsboog voor de meeste mensen

In de pitchbattle van Jong Ondernemen in het FC Groningen-stadion hebben Timo Bos en ik onze onderneming Timmit gepresenteerd. Dat was een echt geweldige ervaring! De competitie stelde ons in staat om ons project aan een breed publiek te tonen, feedback te ontvangen van deskundigen en andere jonge ondernemers. We kunnen met trots zeggen deze te hebben gewonnen, wat ons niet alleen waardevolle erkenning opleverde, maar ook ons netwerk heeft vergroot. Het was een belangrijk moment in onze ondernemersreis en heeft ons aangewakkerd om onze presentatievaardigheden verder te ontwikkelen.

In 2022/2023 hebben Timo Bos en ik deelgenomen aan JA Latvia, een internationaal programma dat jonge ondernemers uit verschillende landen samenbrengt om hun ideeën te presenteren en te ontwikkelen. Tijdens dit programma hebben we niet alleen ons eigen project Timmit gepitcht, maar ook waardevolle kennis opgedaan over ondernemerschap in een internationale context. We waren trots om de Balcia Insurance – Signature Award te winnen, een erkenning voor het innovatieve karakter van ons project en de impact die het kan maken.

De ervaring in JA Latvia was voor ons een belangrijke stap op ons ondernemerspad. Het stelde ons in staat om te leren van andere jonge ondernemers, feedback te krijgen van juryleden en te netwerken met professionals uit de industrie. Het was een inspirerende en motiverende ervaring die ons verder heeft geholpen in het ontwikkelen van onze ideeën en projecten.

Adobe

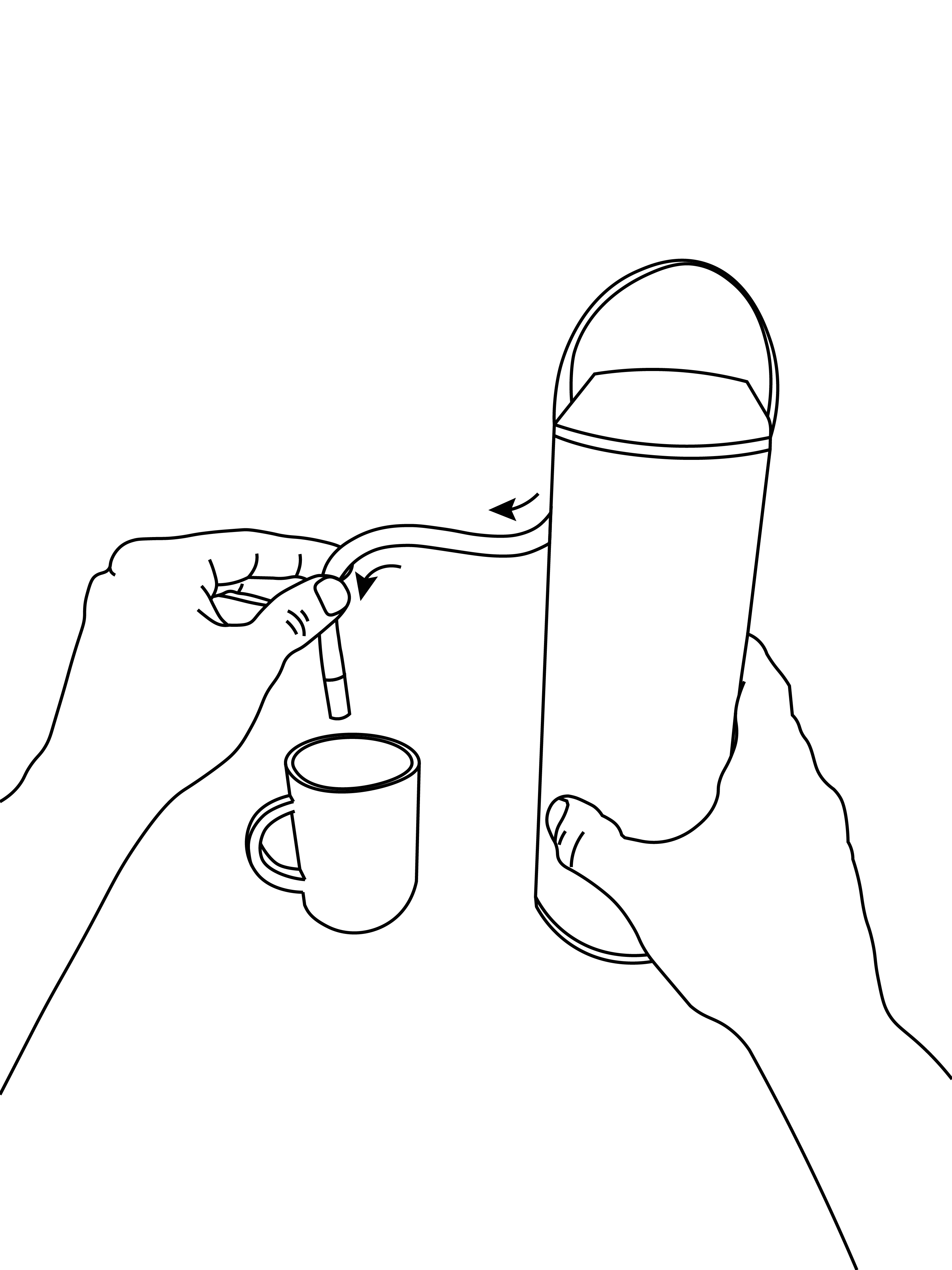

Ik heb tijdens mijn studie veel gebruik gemaakt van Adobe, zo zijn nagenoeg al mijn verslagen erin gemaakt. Ik haal veel plezier uit het maken van templates of opzetjes voor handleidingen/ ontwerpen. Hieronder een boekje dat ik heb gemaakt voor het project TKKK waarin de lancering van een keramieken kandelaar werd bekendgemaakt tijdens de Dutch Design Week.  En ernaast een afbeelding van een handleiding die is gemaakt voor het project Any-timer.

En ernaast een afbeelding van een handleiding die is gemaakt voor het project Any-timer.

Affinity

Momenteel maak ik gebruik van de tegenhangers van Adobe-software, namelijk de programma’s van Affinity. Hoewel ik nog niet hetzelfde niveau van ervaring heb met Affinity als met Adobe, waardeer ik de flexibiliteit en de standpunten van het bedrijf meer. Hieronder een voorbeeld van twee posters die ik heb gemaakt voor bij de pitchbattles die ik heb gedaan bij het Timmit project.

Ik ben 10 jaar geleden begonnen met 3D-printen, wat me de mogelijkheid gaf om veel kennis op te doen over deze technologie. Na het gebruik van verschillende 3D-printers en -soorten, heb ik deze kennis verder kunnen ontwikkelen, vooral tijdens mijn studie. Ik heb 3D-printen veel gebruikt voor het versnellen van iteraties. Deze ervaring stelt me in staat om snel ideeën te testen en te verfijnen. De foto hier linksonder laat het vele itereren bij het mallen project goed zien. Op de foto ernaast zie je een uitgeprint model van de stad Groningen die ik heb gemaakt door publieke (hoogte)data te verwerken met zelfgeschreven scripts.

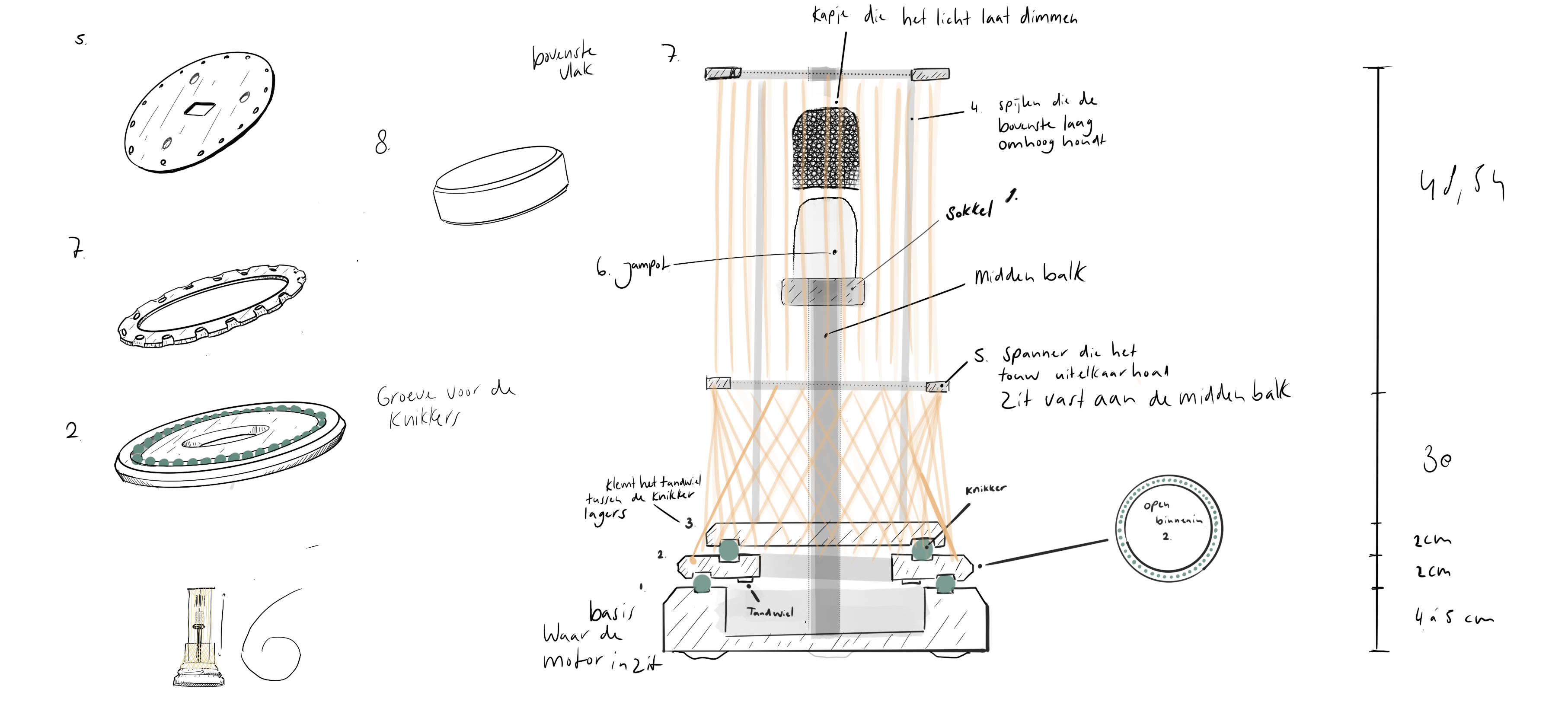

Met de Rotann jampotlamp heb ik veel geleerd over mechanische overbrengingen en het CNC frezen van een product. Zo is de lamp opgebouwd uit uitgefreesde ringen en wordt hij omhoog gehouden door 3 spijlen. Binnenin de lamp zit een kleine stappenmotor die opzichzelf niet sterk genoeg was om de lamp te laten draaien, daarom is er een planetaire tandwielenset aan toegevoegd die hem meer kracht geeft en een tragere rotatie. De lamp rolt op knikkers die fungeren als rollagers. middels zijn rotatie wordt de tijd aangegeven op de zijkant (zie de post-it bovenaan). Hieronder wat schetsen van de keuzes en het ontwerp.

Met de Rotann jampotlamp heb ik veel geleerd over mechanische overbrengingen en het CNC frezen van een product. Zo is de lamp opgebouwd uit uitgefreesde ringen en wordt hij omhoog gehouden door 3 spijlen. Binnenin de lamp zit een kleine stappenmotor die opzichzelf niet sterk genoeg was om de lamp te laten draaien, daarom is er een planetaire tandwielenset aan toegevoegd die hem meer kracht geeft en een tragere rotatie. De lamp rolt op knikkers die fungeren als rollagers. middels zijn rotatie wordt de tijd aangegeven op de zijkant (zie de post-it bovenaan). Hieronder wat schetsen van de keuzes en het ontwerp.

Vanaf het begin van mijn studie ben ik gefascineerd door CNC-frezen. Bij het project Timmit heb ik geleerd hoe zo’n machine werkt en na een jaar ermee te hebben gewerkt, besloot ik er zelf een aan te schaffen om mijn kennis verder te verbreden. Met de CNC-machine heb ik gewerkt aan verschillende projecten, Éen van deze projecten was het verwerken van beschadigde vinylplaten tot sleutelhangers, plectrums en oorbellen.